Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: BL600EKH

Brand: Bole Machinery

Type: Preform Injection

Structure: Horizontal

Plastic Type: Thermoplastic

Plasticizing Way: Screw Type

Clamping Way: Hydraulic & Mechanical

Automation: Automatic

Computerized: Computerized

Certification: SGS

Bole: All Electric Injection Molding Machine

Packaging: standard export packing

Transportation: Ocean

Place of Origin: Zhejiang, China

Payment Type: L/C,T/T

Incoterm: FOB

1. Product Instructions

EKH系列技术参数表 UNIT BL600EKH/C4700 国际标准规格 International specification 4700 螺杆直径 Screw diameter Screw specifications A B C mm 80 90 100 螺杆长径比 Screw L/D ratio 24 21 19 理论注射容积 Theoretical injection capacity cm3 2286 2893 3572 注射量

(以PS计) Shot weight(PS) g 2103 2662 3286 oz 74.3 94.1 116.1 最大对空注射速率 Injection rate into Air cm^3/s 619 783 967 最大对空注射速率 g/S 563 713 880 注射压力 Injection pressure MPa 206 163 132 理论塑化速度 Theoretical plasticizing speed g/S (PS) 88 121 155 注射行程 Injection stroke mm 455 最大注射速度 Max. injection speed mm/s 123 最大螺杆转速 Screw speed r/min 153 系统压力 Sys. Pressure MPa 17.5 电机总功率 Pump Motor(Min~Max) kW 67.1~73.2 电机数量 number of Motors PCS 2 预塑电机功率 (1850-4000吨标配) Pre-plastic motor power Optional 电热功率 Heater power kW 36.1 温控区数 Number of temp. control zones 5+1 锁模力 Clamping force kN 6000 开模行程 Opening stroke mm 900 拉杆内间距 Space between tie bar mm x mm 910×855 最小模具厚度(T型槽) Min. mould height mm 380 最大模具厚度(T型槽) Max. mould height mm 910 最大模板距离(T型槽) Max. Daylight mm 1810 顶出行程 Ejector stroke mm 220 顶出力 Ejector force forward kN 123 顶针回缩力 Ejector force back kN 82 顶出杆数 Number of ejector bar PC 21 干循环时间 Dry Cycle Time S 4.4 能耗(注1) Energy consumption level kW.h/kg ≤0.4(1级) 料斗容积 Hopper capacity kg 100 油箱容量 Oil tank capacity L 750 机械外形尺寸(约) Machine dimensions(L×W×H) m x m x m 9.1x2.2x2.9 机器重量(约) Machine weight Ton 22

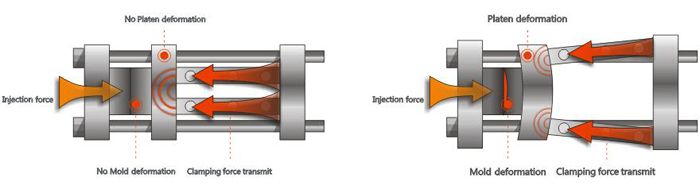

Bole centre clamping structure

■ 100% clamping force use, 10%-20% higher than traditional toggle structure.

■ Less possibility of flash, save flash trim work.

■ Save 2-5% material.

■ Offer good protection to mould, platens and tie bars.

■ Opening stroke 10-20% longer.

Traditional structure

■ With heavy clamping force waste, only 80-85% efficiency.

■ Moving platen with obvious deformation, cause flashes, waste of material and labor of trim the flashes.

Leading technology and performance

China unique producer, central locking toggle

CIML carbon-fiber products intelligent moulding line, made for lightweight of automobile

The performance of Electro- hydraulic hybrid two platen machine has reached the leading level

all electric injection molding machine

4. About Bole Machinery

Product Categories : EKH series hydraulic servo energy saving injection moulding machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.